1

/

van

6

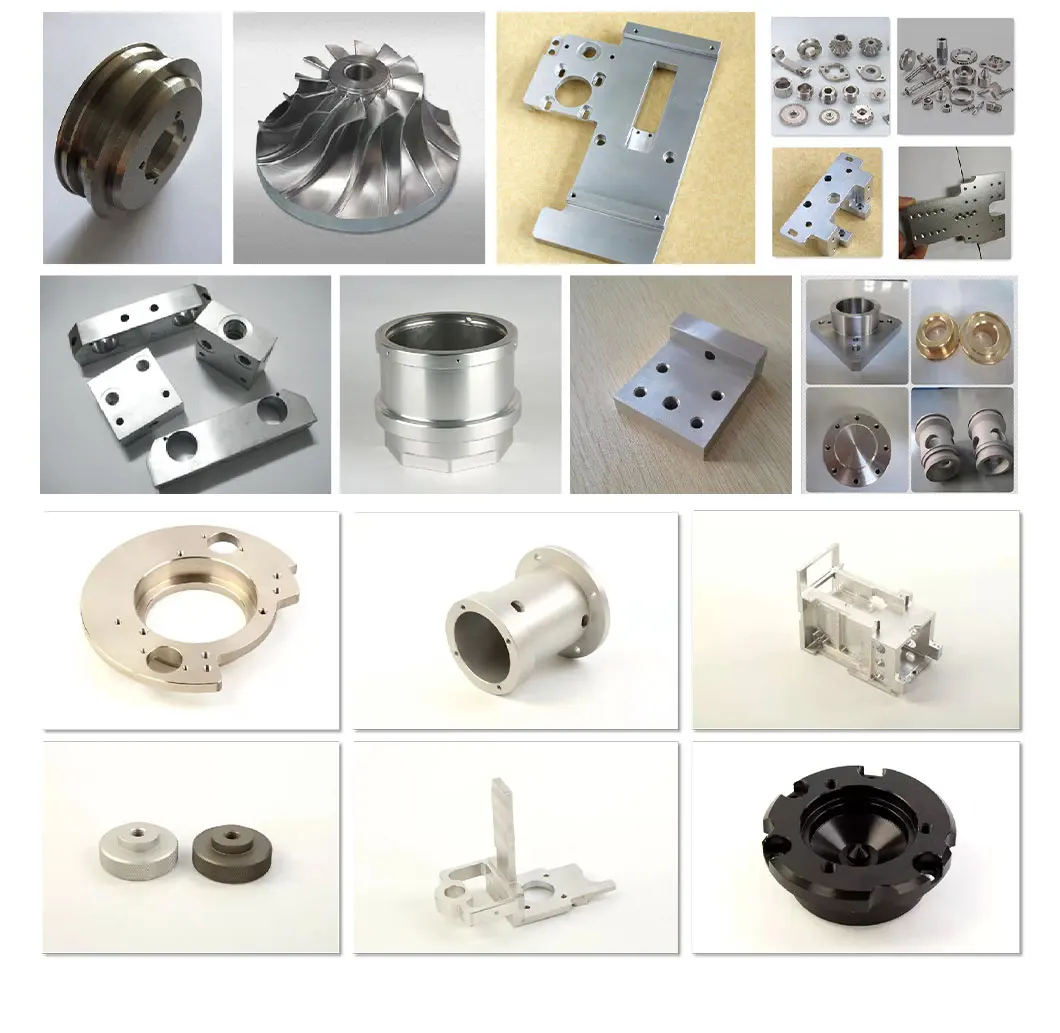

PC Aluminum Shell Phone Cover Players CNC Machining Stainless Steel Material Rapid Prototyping and Drilling-Model CNC Machining

PC Aluminum Shell Phone Cover Players CNC Machining Stainless Steel Material Rapid Prototyping and Drilling-Model CNC Machining

gtooza.com

Normale prijs

$4.99 USD

Normale prijs

$7.49 USD

Aanbiedingsprijs

$4.99 USD

Eenheidsprijs

/

per

Kan beschikbaarheid voor afhalen niet laden

Share

CNC Machining or Not:Cnc Machining

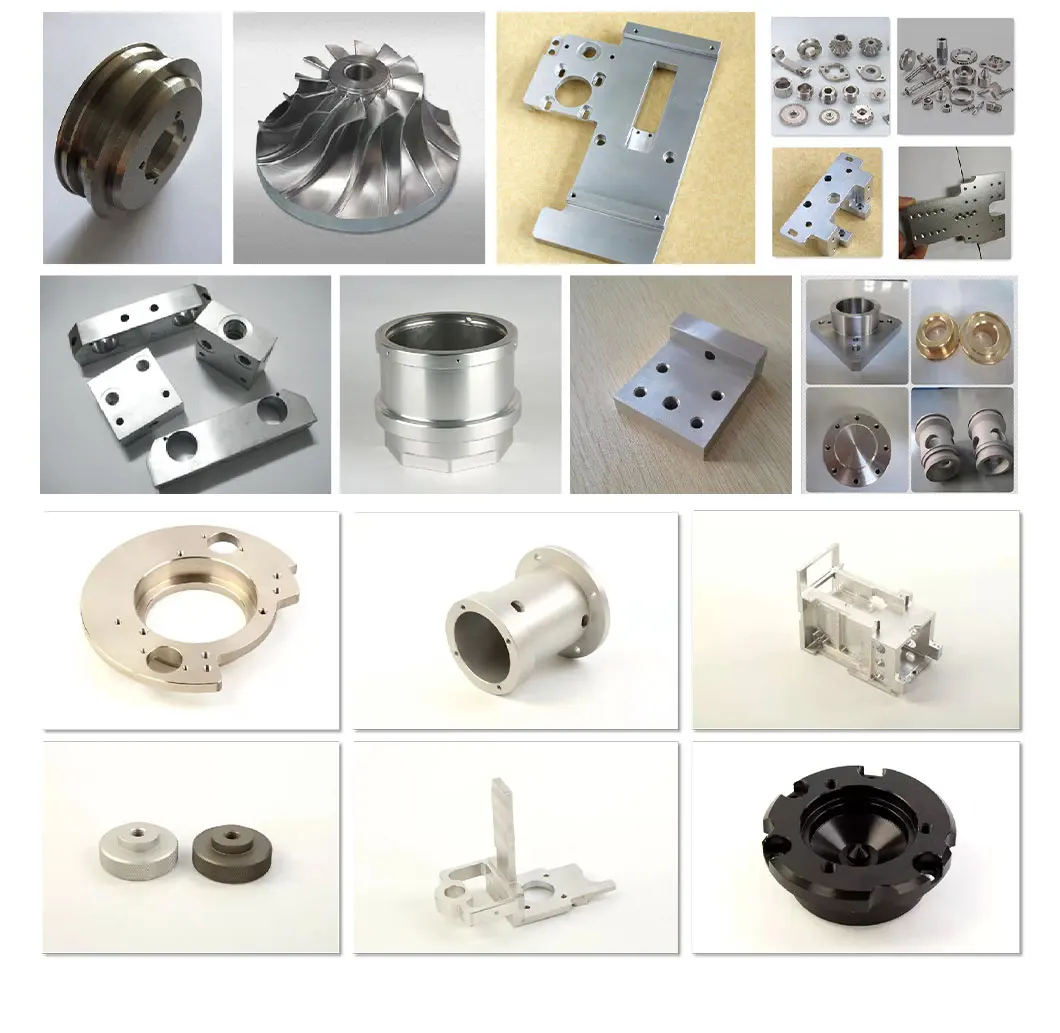

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities:Copper, Aluminum, Brass, Bronze, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not:Micro Machining

Place of Origin:Zhejiang,

:JINTU

Material:Customers' Requirement

MOQ:1 Piece

Surface treatment:Customer's Request

OEM/ODM:Accecpted

Tolerance:0.01mm

Product name:Professional Precision Cnc Machining Parts

Process:Cnc Machining+deburrs

Service:Customized OEM

Color:Customized Color

Equipment:CNC Machining Centres

Q1 : Do you customize products according to our design drawings ?

A1 : Yes, we are a professional metal manufacturing factory with experienced engineering team, which can make customized products

according to customer drawings.

Q2 : Will my design drawings be safe when you get it ?

A2 : Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the

drawings.

Q3 : Does the have the capacity for mass production?

A3 : The has independent production and large-scale production conditions, one-stop service,70 CNC machine tools,40

injection molding machines, and has its own mold workshop.

Q4 : How to deal with surface treatment problems?

A4 : Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective

products.

Q5 : How to avoid mass order quality problems?

A5 : Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as

the key point of quality control, follow up the inspection and defense throughout the process.

Alle details bekijken

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities:Copper, Aluminum, Brass, Bronze, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not:Micro Machining

Place of Origin:Zhejiang,

:JINTU

Material:Customers' Requirement

MOQ:1 Piece

Surface treatment:Customer's Request

OEM/ODM:Accecpted

Tolerance:0.01mm

Product name:Professional Precision Cnc Machining Parts

Process:Cnc Machining+deburrs

Service:Customized OEM

Color:Customized Color

Equipment:CNC Machining Centres

|

Material: |

Aluminum (6061-T6, 6063, 7075-T6,5052) etc... |

|

|

Brass/Copper/Bronze etc... |

|

|

Stainless Steel (201, 302, 303, 304, 316, 420, 430) etc... |

|

|

Steel (mild steel, Q235, 20#, 45#) etc... |

|

|

Plastic (ABS, Delrin, PP, PE, PC, Acrylic) etc... |

|

Process: |

CNC Machining, turning,milling, lathe machining, boring, grinding, drilling etc... |

|

Surface treatment: |

Clear/color anodized; Hard anodized; Powder-coating;Sand-blasting; Painting; |

|

|

Nickel plating; Chrome plating; Zinc plating; Silver/gold plating; |

|

|

Black oxide coating, Polishing etc... |

|

Gerenal Tolerance:(+/-mm) |

CNC Machining: 0.005 |

|

|

Turning: 0.005 |

|

|

Grinding(Flatness/in2): 0.005 |

|

|

Wire-Cutting: 0.003 |

|

Certification: |

CE,ISO9001:2015,ISO14001:2015 |

|

Experience: |

14 years of CNC machining products |

|

Packaging : |

Standard: carton with plastic bag protecting |

|

Lead time : |

For large quantity: pallet or as required |

|

Lead time : |

In general:14-21days |

|

Term of Payment: |

T/T, Paypal, , L/C, etc |

|

Minimum Order: |

Comply with customer's demand |

|

Delivery way: |

Express(DHL,Fedex, UPS,TNT,EMS), By Sea, By air, or as required |

Q1 : Do you customize products according to our design drawings ?

A1 : Yes, we are a professional metal manufacturing factory with experienced engineering team, which can make customized products

according to customer drawings.

Q2 : Will my design drawings be safe when you get it ?

A2 : Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the

drawings.

Q3 : Does the have the capacity for mass production?

A3 : The has independent production and large-scale production conditions, one-stop service,70 CNC machine tools,40

injection molding machines, and has its own mold workshop.

Q4 : How to deal with surface treatment problems?

A4 : Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective

products.

Q5 : How to avoid mass order quality problems?

A5 : Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as

the key point of quality control, follow up the inspection and defense throughout the process.