1

/

จาก

6

High Permance Small Cutting Grass Cutter Trimming Scissors Japanese Farming Tools

High Permance Small Cutting Grass Cutter Trimming Scissors Japanese Farming Tools

gtooza.com

ราคาปกติ

$61.84 USD

ราคาปกติ

$92.76 USD

ราคาโปรโมชัน

$61.84 USD

ราคาต่อหน่วย

/

ต่อ

ไม่สามารถโหลดความพร้อมในการรับสินค้าด้วยตนเองได้

Share

place of origin:Japan

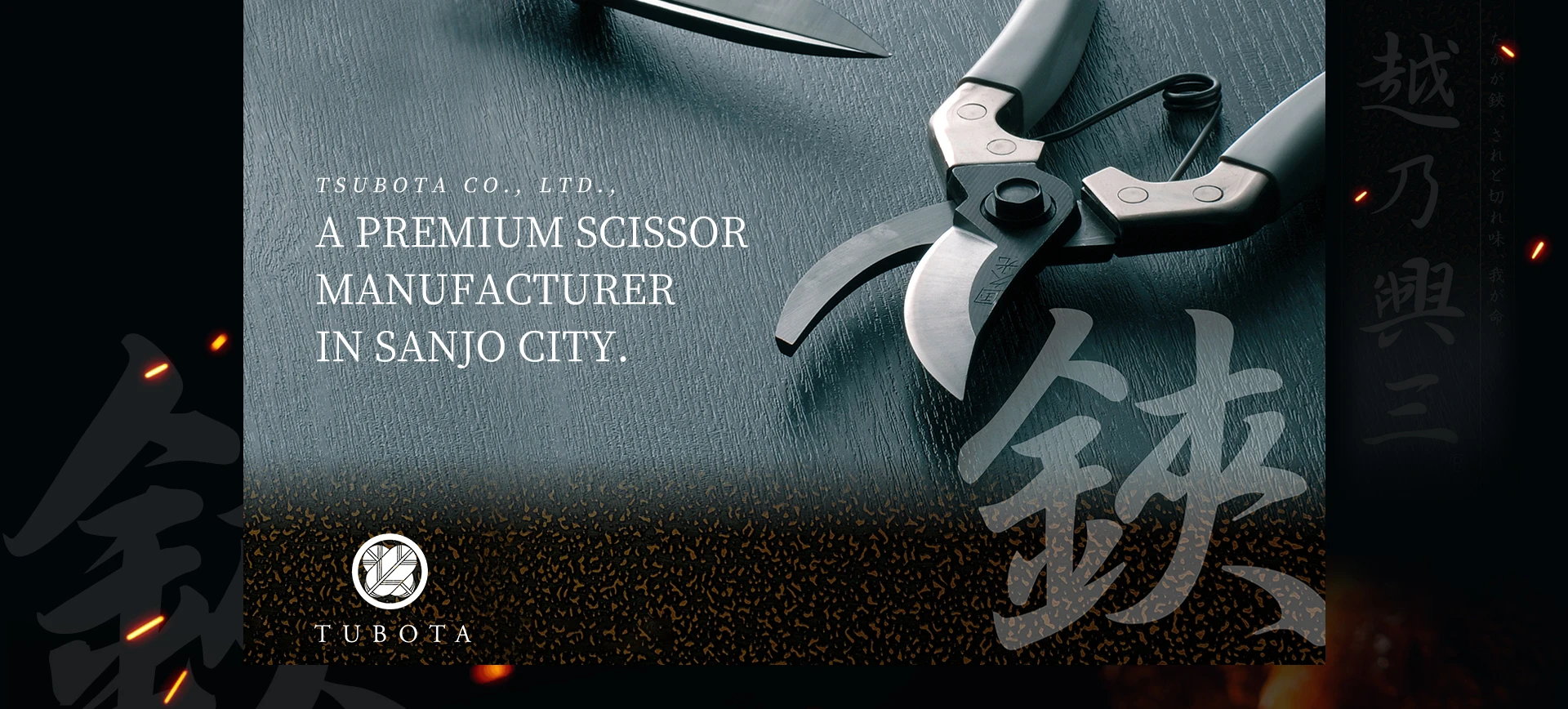

brand name:TSUBOTA CO., LTD.

model number:P23-05

power:Manual

customized support:Please contact us

Products Description

8112 Tanemitsu SLD Curved 270

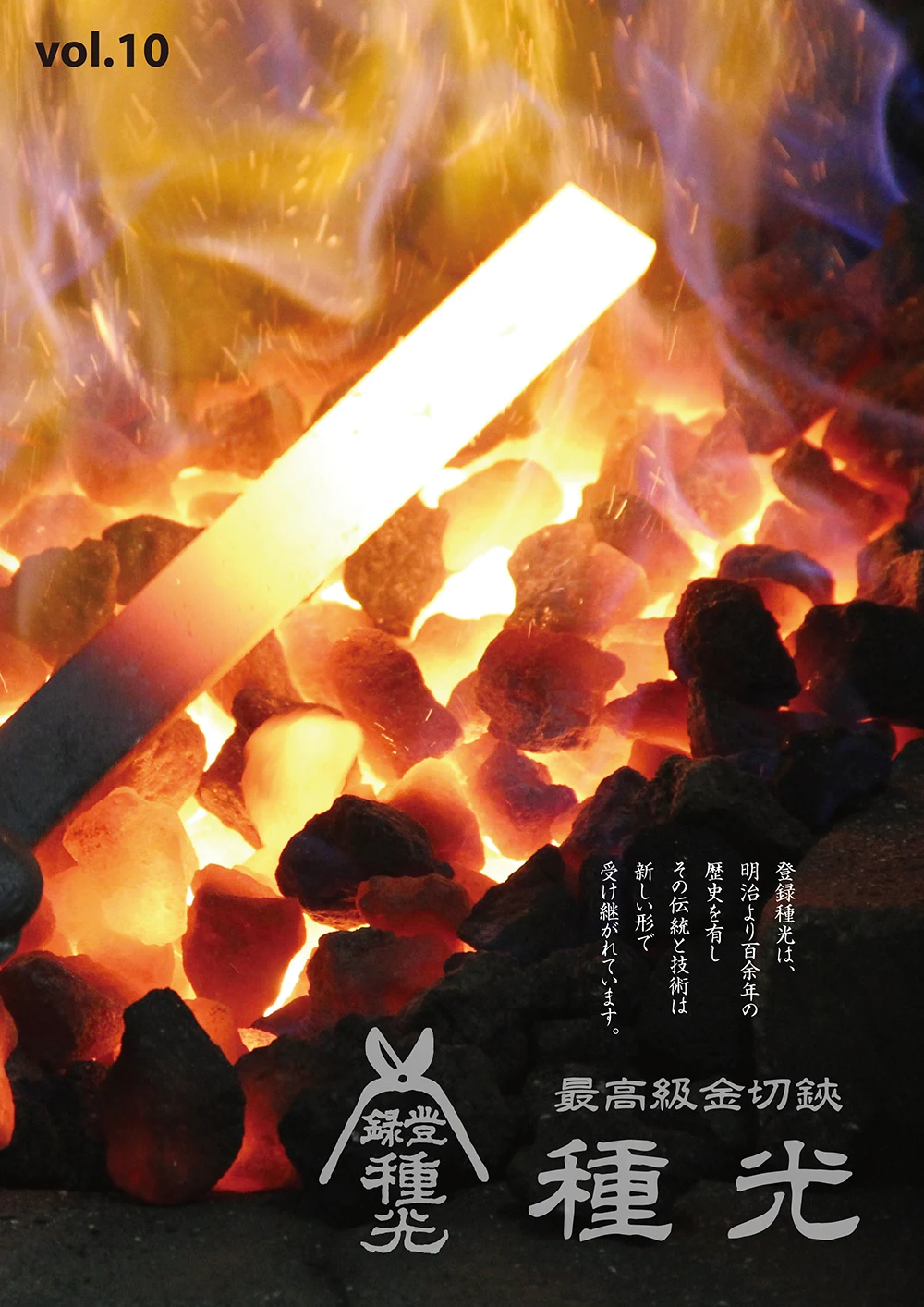

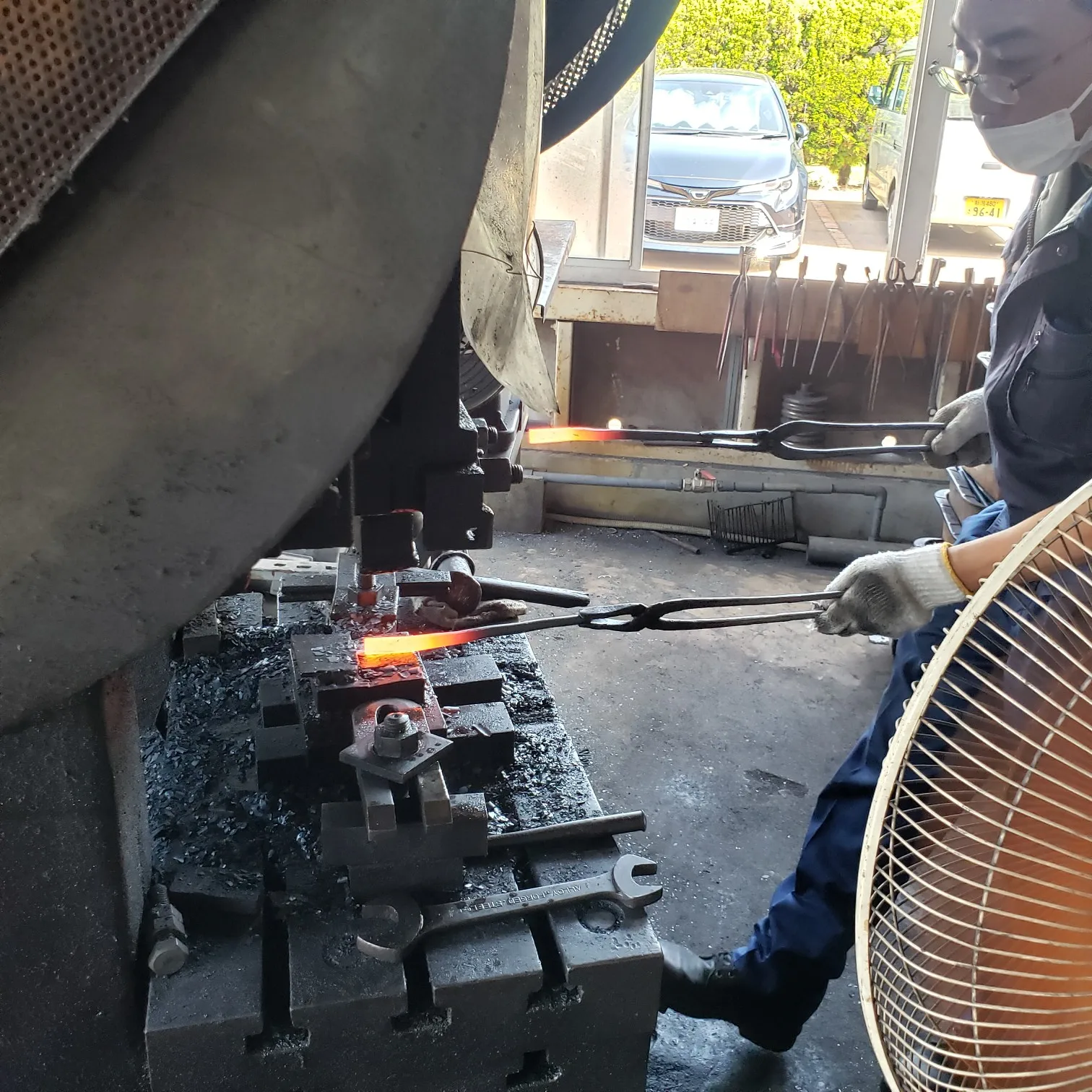

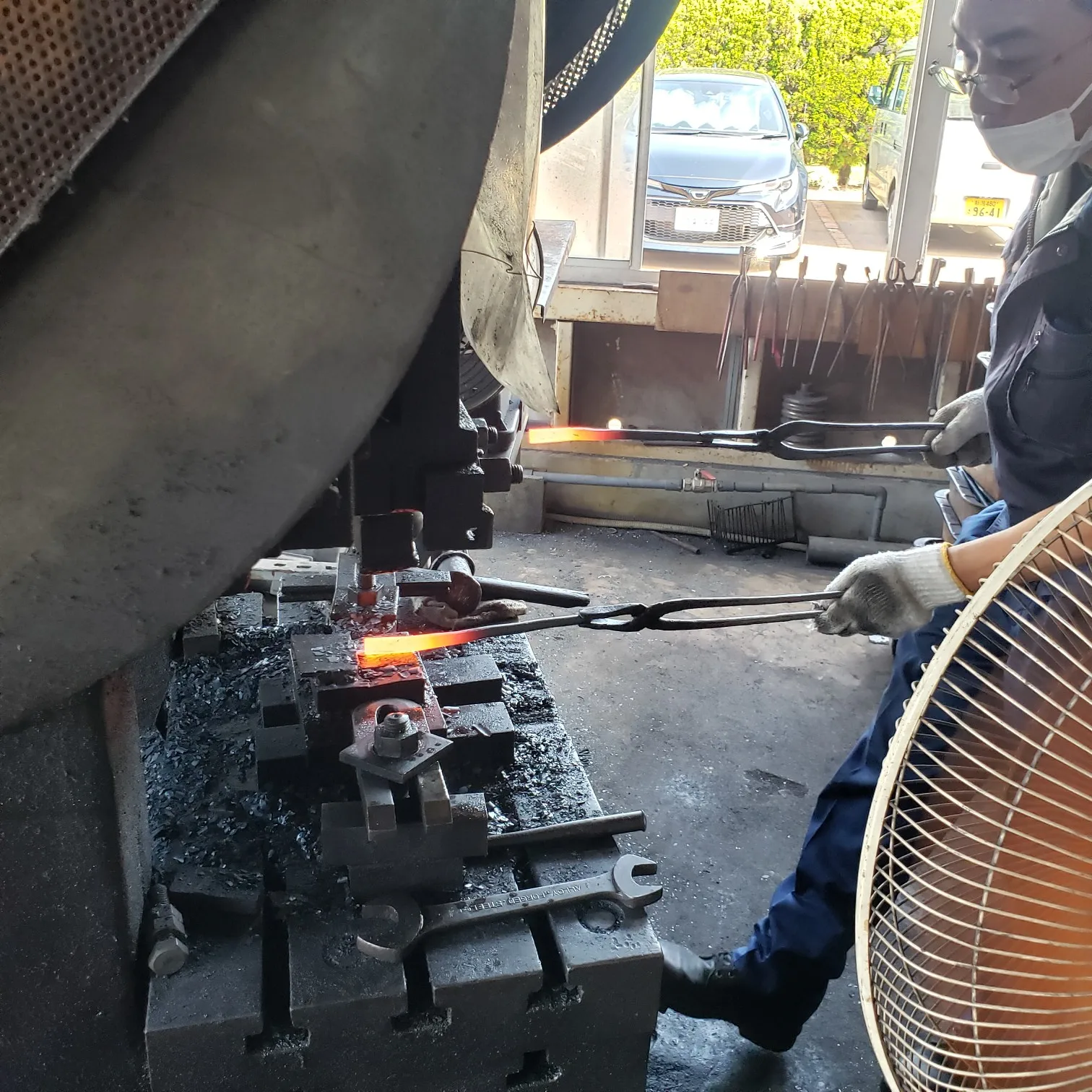

銉籘oroku Tanemitsu metal shears have a history going back more than a century to the Meiji period, and we carry on those traditions and techniques in new forms. 銉籘he Top Class Metal Shears Toroku Tanemitsu series is made using traditional methods by Tsubota, a specialist scissors manufacturer in Sanjo, Japan. The blades are made from the highest grade of Yasuki SLD steel, and each pair is a superb article made by an integrated manufacturing process of forging, cladding in steel using traditional methods, and traditional tempering. In addition, we carry a vast lineup with more than 300 items from series made from the highest grade steel, including Super High Speed 21, HAP High Speed, ZDP189, and Big Cut. • What is Yasuki steel? • For centuries, Tamahagane steel made from extremely pure iron sand was used as the material for the finest Japanese swords. This tradition of Tamahagane steel is still carried on today in new forms, and produces reliably high-quality steel with extremely few impurities. • What is forging? This technique is used to shape and harden material by heating it and hammering it, and forging creates a finer structure in the steel, making it harder and tougher. • What is cladding? By combining steel and another metal to create a blade with two layers, it is possible to use a steel with high hardness for the steel part, increasing the overall hardness. However, since it combines two layers of different materials, it is prone to warping during manufacturing, and requires a lot of work by hand, so this method is generally used mostly by high-grade blade manufacturers. • Traditional hot bath quenching The quenching vessel is filled with a solution heated to a quenching temperature suitable for the steel (1000°C or higher), and the steel parts are kept in the hot bath to produce a uniform hardness to the core of the steel. In contrast, there are also quenching techniques that only harden the surface, similar to plating. The combination of cladding and traditional quenching produces uniform high hardness that can withstand repeated sharpening, making shears that can be restored to near the sharpness of when they were new.

• Curved Blades 270 Shears • There all-purpose professional shears have curved blades for making curved or straight cuts. For sheet metal thickness of roughly 0.35mm to 0.4mm • User Precautions • Each item is individually handmade, so the weight and dimensions may vary slightly. • The tips of the blades are sharp, so be very careful when using them. • Store them out of the reach of children. • When cutting thick or hard material, cut a little at a time while rotating the piece, and avoid twisting the blades. • These are flower cutting shears, so do not use them to cut metallic objects like iron or galvanized sheet metal.

Company Profile

We manufacture the highest quality metal cutting shears and gardening bonsai shears. Using the finest Yasuki steel, each piece is handcrafted through traditional forging, steel bonding, and hardening techniques, ensuring all processes are completed in-house.

- Steel Bonding Method: This method uses a two-layer material combining steel and base metal for the blade, allowing the use of high-grade steel for the cutting edge, resulting in higher hardness and superior durability.

- Traditional Heat Bath Hardening: By immersing the blade in a heated solution during the hardening process, we achieve uniform hardness throughout the steel core. Combining the steel bonding method with traditional hardening techniques, our shears offer consistent high hardness and can be sharpened to restore their original cutting edge.

gtooza.com

ดูรายละเอียดทั้งหมด

brand name:TSUBOTA CO., LTD.

model number:P23-05

power:Manual

customized support:Please contact us

Products Description

8112 Tanemitsu SLD Curved 270

銉籘oroku Tanemitsu metal shears have a history going back more than a century to the Meiji period, and we carry on those traditions and techniques in new forms. 銉籘he Top Class Metal Shears Toroku Tanemitsu series is made using traditional methods by Tsubota, a specialist scissors manufacturer in Sanjo, Japan. The blades are made from the highest grade of Yasuki SLD steel, and each pair is a superb article made by an integrated manufacturing process of forging, cladding in steel using traditional methods, and traditional tempering. In addition, we carry a vast lineup with more than 300 items from series made from the highest grade steel, including Super High Speed 21, HAP High Speed, ZDP189, and Big Cut. • What is Yasuki steel? • For centuries, Tamahagane steel made from extremely pure iron sand was used as the material for the finest Japanese swords. This tradition of Tamahagane steel is still carried on today in new forms, and produces reliably high-quality steel with extremely few impurities. • What is forging? This technique is used to shape and harden material by heating it and hammering it, and forging creates a finer structure in the steel, making it harder and tougher. • What is cladding? By combining steel and another metal to create a blade with two layers, it is possible to use a steel with high hardness for the steel part, increasing the overall hardness. However, since it combines two layers of different materials, it is prone to warping during manufacturing, and requires a lot of work by hand, so this method is generally used mostly by high-grade blade manufacturers. • Traditional hot bath quenching The quenching vessel is filled with a solution heated to a quenching temperature suitable for the steel (1000°C or higher), and the steel parts are kept in the hot bath to produce a uniform hardness to the core of the steel. In contrast, there are also quenching techniques that only harden the surface, similar to plating. The combination of cladding and traditional quenching produces uniform high hardness that can withstand repeated sharpening, making shears that can be restored to near the sharpness of when they were new.

• Curved Blades 270 Shears • There all-purpose professional shears have curved blades for making curved or straight cuts. For sheet metal thickness of roughly 0.35mm to 0.4mm • User Precautions • Each item is individually handmade, so the weight and dimensions may vary slightly. • The tips of the blades are sharp, so be very careful when using them. • Store them out of the reach of children. • When cutting thick or hard material, cut a little at a time while rotating the piece, and avoid twisting the blades. • These are flower cutting shears, so do not use them to cut metallic objects like iron or galvanized sheet metal.

|

Size |

Total length approx. 290 mm |

|

Materials |

Blade/Yasuki SLD steel, Body/Iron: plated |

|

Weight |

approx. 630g |

Company Profile

TSUBOTA CO., LTD.

We manufacture the highest quality metal cutting shears and gardening bonsai shears. Using the finest Yasuki steel, each piece is handcrafted through traditional forging, steel bonding, and hardening techniques, ensuring all processes are completed in-house.

- Steel Bonding Method: This method uses a two-layer material combining steel and base metal for the blade, allowing the use of high-grade steel for the cutting edge, resulting in higher hardness and superior durability.

- Traditional Heat Bath Hardening: By immersing the blade in a heated solution during the hardening process, we achieve uniform hardness throughout the steel core. Combining the steel bonding method with traditional hardening techniques, our shears offer consistent high hardness and can be sharpened to restore their original cutting edge.

gtooza.com